-

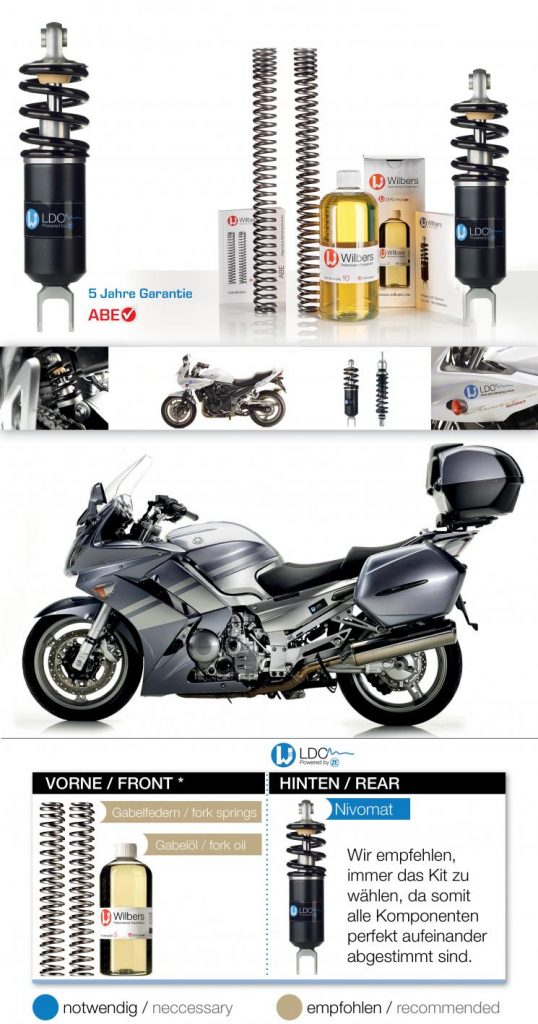

Wilbers LDC Nivomat Mono Shock Kit$3,117.00 inc GST

Wilbers LDC Nivomat Mono Shock Kit$3,117.00 inc GST -

Wilbers LDC Nivomat Mono Shock$2,739.00 inc GST

Wilbers LDC Nivomat Mono Shock$2,739.00 inc GST -

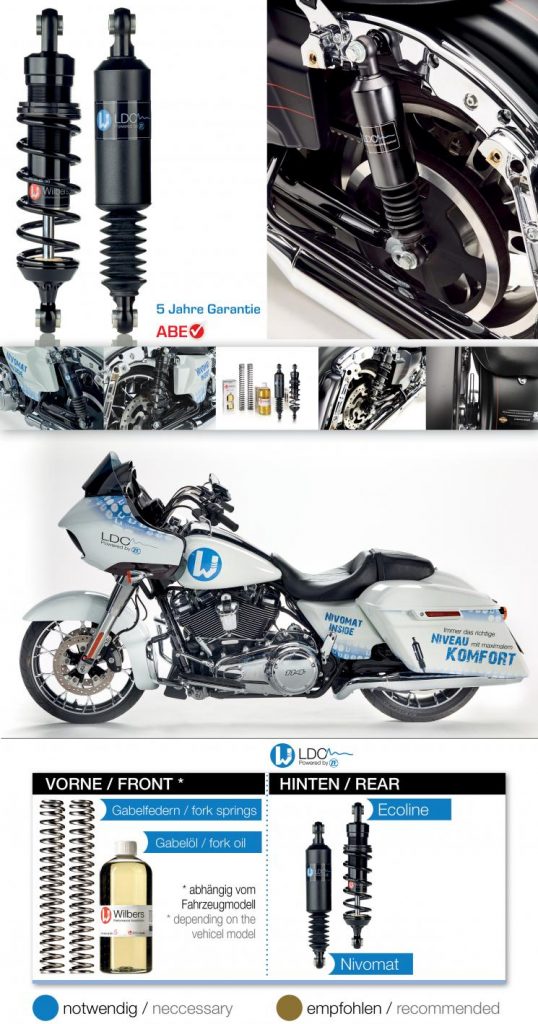

Wilbers LDC Nivomat Twin Shock Kit$4,468.00 inc GST

Wilbers LDC Nivomat Twin Shock Kit$4,468.00 inc GST

-

Wilbers LDC Nivomat Mono Shock Set$4,270.00 inc GST

Wilbers LDC Nivomat Mono Shock Set$4,270.00 inc GST

The chassis geometry and tuning is the most important thing to be able to ride a motorcycle safely and comfortably.

The ride heights at the front and rear have a significant effect on handling. Depending on the set-up and driver’s weight, these values vary and are usually not on the same level. A suspension spring that is too soft or too hard also affects the ride height and causes an unwanted change in the geometry.

The search for an optimal solution for high loads, heavy or light passenger, rides with or without luggage is always based on the spring preload. An increased or reduced spring preload, in combination with an adjusted damping rate, can mean a slight improvement – but it is always associated with compromises.

High comfort with the best traction is usually only achieved with soft springs or little damping. The correct spring preload in solo operation ensures optimal chassis geometry. With a load – in the form of luggage or a passenger – you ride lower, despite increased spring preload.

It remains a compromise solution, even if the damping is adjustable. If the spring is too soft, it bottoms out regardless of the preload and causes the vehicle to sink deeper.

The only solution to payload would be a stiffer spring paired with an adjusted damping rate. Unfortunately, this is not readily possible unless the Wilbers Nivomat system is used. A gas spring

significantly increases the load capacity. The gas cushion automatically adjusts the spring rate and damping to the required values through pumping movements.

The patented Wilbers Nivomat system automatically ensures sufficient spring rate, damping and spring deflection without manual adjustments – completely independently via the hydropneumatic function and always ideal for the payload.

Developed in cooperation with ZF from the OEM car sector, the Wilbers Nivomat system achieves an unprecedented level of functionality and quality.

The LDC Nivomat Twin Shock Kit is delivered in connection with a Wilbers Ecoline suspension strut in the Nightline version as well as the necessary ZERO friction fork springs and ZERO friction fork oil.

It was specially developed for the Harley Davidson touring models. Because this is where the Nivomat can exploit its full potential: some of these models are equipped with just 53 mm of spring travel on the rear wheel as standard.

The LDC Nivomat Twin Shock System, on the other hand, has 73 mm of spring travel and, in combination with the automatic level control, always ensures the best possible comfort and maximum spring travel.

The LDC Nivomat Twin Shock Kit is now also available for models from other manufacturers.

After the presentation and the first test reports of the Sportster 1250S, it was clear to us that after the great success of the LDC system for the touring models, we now urgently need to develop an LDC system for the Sportster 1250S.

Because here, too, the standard built-in conventional spring strut quickly reaches its limits. Unfortunately, the sensational design and the belt drive of the Sportser 1250S do not allow for much spring travel, which inevitably leads to a tight adjustment with normal spring struts.

The Wilbers LDC chassis also provides the solution here: The spring travel increases to a whopping 80 mm and the spring rate could be significantly reduced due to the additional gas spring, which becomes harder depending on the load condition. It is important to mention that the seat height does not change significantly and thus the stocky look of the Sportster 1250S is retained.

The Wilbers LDC system provides the necessary comfort without sacrificing stability and handling.

Of course, we also took a closer look at the fork of the Sportster 1250S during the development of the LDC suspension. We have succeeded in significantly improving the friction and thus the response behavior with high-quality sliding bushes and SKF Simmerrings. The slightly firmer Zero Friction fork springs in combination with the matching Zero Friction fork oil form the perfect symbiosis.

For the best driving experience, the LDC shock absorber is therefore supplied together with the fork components as a suspension kit.

It consists of:

· LDC mono shock absorber

· 1 set of ZERO friction fork springs

· 1 liter of ZERO friction fork oil

· 2 sets of ZERO friction slide and guide bushes

· 2 sets of SKF oil seals and dust caps

Do you also want optimal handling for your large enduro, regardless of the payload, whether solo, with a passenger and/or luggage, without constant adjustments to the chassis?

With the LDC Nivomat big enduro, specially developed for these motorcycles, you always ride at the optimum ride height – perfectly tuned. It doesn’t matter whether you’re on a trip around the world, alone, with a passenger, fully loaded or whether you’re just making a short trip, the traction of your large enduro has never been better.

As with all other LDC Nivomat systems, the damping and the spring rate adjust automatically here too, without any buttons or electronics. This hydropneumatic function is a development cooperation between ZF and Wilbers Products that has never existed in this form before. All functions in one system, with maximum driving comfort and a long service life.

When you place an order, we need the weight of your rider, passenger and luggage – after all, we produce an individual solution for each customer.

We are currently developing a black box for vehicles with Dynamic ESA, which deactivates the control of the rear ESA shock absorber. This ensures that there are no error messages on the display and that the vehicle electronics function as usual in all other areas. The front ESA shock absorber can therefore continue to be used without functional restrictions.

The LDC Nivomat Mono is used in vehicles that are equipped with a central spring strut as standard. As with all other spring struts from Wilbers, we attached great importance during the development phase to finding an optimal basic setup for each individual motorcycle.

Only after extensive test bench runs, installation tests and test drives is the LDC Nivomat Mono released for the respective motorcycle. This is how we ensure that the LDC Nivomat system adapts optimally to every load. For the best possible overall tuning of the chassis, we recommend replacing our ZERO friction fork springs together with the ZERO friction fork oil. These are already included in our LDC Nivomat Mono Kits.

Although the system adapts to the load, we also ask about the driver’s weight and the payload here. The background is that we want to provide you with an optimal basic set-up so that the system does not already use up its reserves for the minimum load requirement.

- The Wilbers LDC Nivomat system is based on details from the well-known and patented car Nivomat system and offers an unprecedented function. The system promises a fully automatic hydropneumatic

level control system with maximum comfort. - No driver intervention is required to activate and operate the system.

- The core advantage of the Wilbers LDC is the combination of level control and the

progressive behavior of the spring rate and damping that adapts to the load. - Level control, damping adjustment and spring rate: all functions are in a single housing

- housed and are activated and controlled purely mechanically and hydraulically.

- The Wilbers LDC is active and ready for use as soon as you start your journey.

Wilber’s LDC Nivomat Mono Shock Set

The “Wilbers LDC” Mono Shock Set offers excellent comfort in all circumstances. It adapts to different loading situations without any effort on the riders part, automatically without any buttons or electronics! After the passenger with or without luggage takes a seat, the deeply compressed suspension pumps itself up after a few meters of riding, back to the defined riding level as the shock absorber delivers additional oil into its cylinder by its own stroke movement. The resulting pressure increase leads to the adjustment in damping.

Suspension kit includes:

– Nivomat

– Shock Absorber Type 630 Edition Blackline

Product may vary from picture.

Wilber’s LDC in detail

How does the LDC Nivomat work?

The LDC Nivomat Mono consists of two separate oil chambers, a thick piston rod, a

mechanical pump rod including a pressure valve and a short, external suspension spring.

With the oil chambers, a distinction is made between the external low-pressure chamber and the gas-assisted internal high-pressure chamber. If the shock absorber is now loaded, the rod automatically pumps oil from the low-pressure to the high-pressure chamber through its up and down movement while driving and the piston rod is moved out of the damper. This pumping process lasts exactly as long as it takes for the motorcycle to find its balance again – the shock absorber automatically adjusts its level after about 300 meters of driving.

With the LDC Nivomat Twin Shock, these system functions are divided into two individual components. The conventional Ecoline spring strut is equipped with the spiral steel spring and takes over part of the overall

damping. The Nivomat regulates the level and, depending on the load, adjusts the overall spring rate and the damping that is additionally required. All this without the driver

having to intervene in the system.

The principle

- The LDC Nivomat system is preset so that it immediately drops to the intended

(defined) level for solo use, namely approx. 1/3 of the total spring travel. In this state, the system offers a reduced spring rate and damping for solo use compared to a conventional shock absorber, thus ensuring maximum comfort without rebounding.

- If the passenger and/or luggage are loaded, the vehicle sinks in deeply and negatively changes the vehicle geometry. In this case, the preloading of the spring would be necessary with a “normal” shock absorber, but this only adjusts the level position. The actually necessary adjustment of the spring rate does not take place.

- After driving approx. 300 meters under load, the LDC strut brought the vehicle back to the defined level. The inner pump rod pumped oil from the low pressure to the high pressure chamber. Due to the increased high pressure, the vehicle is raised to the defined level and at the same time the spring rate and damping are adjusted to the load. Level, vehicle geometry, spring rate and damping are optimized throughout the journey and thus ensure maximum comfort and driving safety.

The Nivomat in section

The low-pressure chamber is on the outside and the high-pressure chamber with the gas cushion is on the inside. Under

load, the rod in the middle pumps oil from the low pressure chamber to the high pressure chamber – the piston rod extends and the spring rate increases progressively.

Advantages of the Wilbers LDC compared to conventional shock absorbers

| Conventional strut | Wilber’s LDC Nivomat |

| Seat height changes depending on the payload and luggage. | Consistent seat height, regardless of the load. |

| Reduced total suspension travel depending on load and luggage. | Full availability of the total suspension travel when loaded. |

| Different geometry depending on payload and luggage. | Consistent geometry, regardless of the load. |

| Loss of ground clearance depending on payload and luggage. | The Wilbers LDC always returns to the defined level and thus ensures optimum ground and leaning clearance. |

| Suspension spring with linear or progressive characteristic. Can only be optimally designed for one loading condition. If the load frequently changes between solo and pillion use and/or luggage, the level position can only be achieved by adjusting the spring preload. The actually necessary adjustment of the spring rate is not possible. | Additional gas spring with progressive characteristic: automatically adjusts to the load and always offers an optimal spring rate and damping. |

Advantages:

- Constant subjective driving experience, whether solo, with a passenger and/or luggage.

- Automatic adjustment of the spring and damping rate to the load condition.

- If the loading situation changes, no setting or adjustment is necessary.

- Incorrect operation is thus excluded, since there are no adjustment options.

- Since the necessary spring and damping rates are called up, the system offers maximum comfort.

- The maximum spring deflection is always available, thus also the maximum freedom from lean angles with every load.

Email: sales@selectedge.com.au or Phone: (03) 9467-7622